authorities wanted to

move from that place

to some other areas.

Taking advantage of

this, Mr Lieu took

27,000 square metres

of land on rent for a

term of twenty years and started his project. The factory

started manufacture in 1998.

The factory was built with different areas such as

Withering Troughs, Processing Room, Sorting Room,

Packing Room, Office and Stores for materials.

Machineries were invested in.The factory also organized

its own Management Board, which in conformity with

the law of Enterprise, selected and trained many skilled

workers in manufacturing and grading of teas.This helped

the factory in exporting teas to South-east Asian

countries and some to the European market too. The

expansion work progressed well and with a capacity of

only 6,000 kg of green leaf per day in the year 1998, it

went up to 20,000 kg per day in 2000. From 2006 to

2009, the factory continued expanding for exports and

reached a capacity of 40,000 kg green leaf per day.

Simultaneously, the factory also carried out the project of

‘Component of Clean Manufacture in Industry’ under the

Ministry of Industry & Commerce. Mr Lieu, along with

his wife, two sons and two daughters, personally

supervised the day to day running of Khanh Hoa.

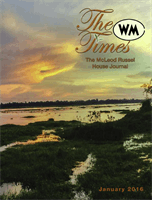

Within the factory premises, Mr Lieu built a beautiful

wooden bungalow where he lived with his family. Best

quality wooden pillars were brought from several

Provinces, and it apparently cost him about $ 40,000 to

build the house in 1998. This was much more than the

expense of a concrete house at that time.

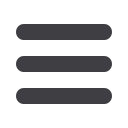

Khanh Hoa also has three ponds covering 5,000 square

metres – one for fish, another for turtles and the third one

as a reserve pond. After the takeover, PhuBen sold fish

worth $ 2,900 in the first year; 50% of the money was

ploughed back into putting some special types of fish in

the pond. All along the ponds, very high yielding litchi

trees have been planted. The

harvested fruit is distributed

amongst all the staff.

Khanh Hoa also has a beautifully laid out garden in the

front yard of the bungalow, which has twelve different

varieties of bonsais that were collected from different

parts of Vietnam. A fountain made of limestone brought

from Da Nang, with a variety of goldfish swimming

around, adds to the visual appeal.

The pathway to Khanh Hoa house and the factory is

planted with palm trees on one side and jasmine shrubs

on the other, which fill the air with a lovely fragrance.

Khanh Hoa is self-

reliant with its own

canteen which serves

tasty and healthy

food.

Organic vegetables

grown

in

the

compound are used,

thus enabling the

workers to procure

meals at a subsidized rate. A unique rice cooker caters to

the ten staff members and sixty workers.

A Russian model Army Jeep used by an Army General

was gifted to Khanh Hoa during the Vietnamese war.

Good care is taken of the vehicle, which is in perfect

running condition.

As is oft found in family run business ventures, trouble

starts brewing once the patriarch gets on in years and the

children move on to greener

pastures.MrLieu too found

it difficult to keep the company economically viable.

PhuBen Tea Company acquired Khanh Hoa on 9 May

2013 and started manufacturing from the 28th of the

same month, producing 6,00,667 kg of made tea that year.

It is a 100% Black Orthodox tea factory, which

underwent major renovations during the cold weather of

2013/14. The processing room, which was originally

divided into three rooms, was broken to accommodate

on-line Rolling, Fermenting and Drying systems, with

three CMFs. All efforts were made to increase the

capacity and 9,50,384 kg of made tea was produced in

2014. A glass partition separates the processing and the

drying areas.

Mr Lieu’s Bungalow

The Garden

10 January 2016

January 2016 11

The Rice Cooker